Application of ND Steel Tube in auxiliary-economizer of CDQ

Application of ND Steel Tube in auxiliary-economizer of CDQ Boiler

The problem of boiler leakage and tube burst is one of the greatest threats to the normal production of CDQ at present. It has the characteristics of sudden accident, relatively long shutdown time, difficulty in rush repair and great economic loss. There are many reasons for boiler leakage and tube burst, one of which is the corrosion of heating surface tubes. According to the investigation of relevant institutions, almost all economizers and sub-economizers of CDQ boilers in China use carbon steel tubes as heating surface tubes, which have poor corrosion resistance. Water leakage due to corrosion generally occurs within 3-5 years, and the service life of equipment is generally only 5-8 years. As the feed water preheater of CDQ boiler, the secondary economizer is affected by low temperature flue gas dew point corrosion, which has higher probability of water leakage and shorter service life. Once the furnace tube needs to be replaced, the cost of spare parts, construction and insulation is higher. If the loss caused by the shutdown of coke dry quenching is considered, the economic loss will be greater. Therefore, it is of great significance to study the low temperature dew point corrosion resistance of the heating surface tubes of the auxiliary economizer.

In order to slow down the corrosion rate of heating surface pipes in low temperature zone, there are usually two ways: one is to increase the flue gas and feed water temperature in the sub-economizer area to avoid condensation of sulfuric acid vapor and water vapor; the other is to select steel pipes with low temperature dew point corrosion resistance to make heating surface pipes to improve their corrosion resistance. In fact, it is very difficult to increase the flue gas and water temperature in the sub-economizer area of CDQ. Therefore, it is a relatively safe method to use ND steel pipe to manufacture heating surface tubes at present. In this paper, ND steel pipe is used to replace the original 20 steel pipe to manufacture the heating surface tube of the sub-economizer. It is hoped that the heating surface tube of the sub-economizer can be improved by improving the material.Resistance to low temperature dew point corrosion.

1. Cause Analysis of Corrosion of Sub-economizer Pipe

The auxiliary economizer is a preheater before deaeration of feed water of CDQ boiler. It is installed between the outlet of circulating fan and the inlet of chamber of CDQ trough, so it is also called feed water preheater. Usually, light tube contact is used for heat transfer, which consists of upper tube box, lower tube box, bottom flue, top flue and external frame. The upper and lower tube boxes are composed of 68 groups of segments, outer shell of the box and upper and lower headers respectively. Each group of segments is a serpentine pipe welded by 16 layers of horizontal straight pipe and 180 degree elbow pipe. Water and flue gas enter from the lower tube box of the sub-economizer and flow out from the upper tube box. The heating surface of the tube is generally made of 20 steel pipes with a specification of 28 mm x 4 mm (GB3087). The maximum operating pressure of the pipe is 1.47 MPa, the water supply is about 82.1 t/h, the inlet temperature is about 60 C, the outlet temperature is about 120 C, the inlet temperature is usually 160-180 C, and the outlet temperature is usually 120-130 C. The maximum flue gas flow rate is about 214 000 m3/h, the total heat transfer area is 940 m2, and the total weight of the tube bundle is about 28 t.

Among the chemical substances that produce waste gas from coke oven coking, the mass concentration of hydrogen sulfide is generally not more than 6g/m_, the mass concentration of HNC is not more than 1.5g/m_and the volume fraction of carbon dioxide is 2.3%. Therefore, the smoke of CDQ will inevitably carry dust, water vapor, sulfide, cyanide and so on. Harmful substances. Water vapor is easy to dew in low temperature flue gas, and reacts with sulfide to form dilute sulfuric acid, which results in corrosion. This is low temperature corrosion. The mechanism of low temperature corrosion of flue gas is that water vapor and sulfuric acid vapor in low temperature flue gas condense on the low temperature heating surface of boiler, and pitting corrosion occurs in chemical reaction with furnace tube metals, and pitting corrosion occurs preferentially on ferrite near grain boundary. When the pit grows up, it develops preferentially along the rolling direction, forming corrosion grooves, resulting in thinning of wall thickness and mechanical strength of pipe wall.

Reduce water leakage through perforation until failure. The formation of low temperature corrosion depends on three factors: acid deposition, heating surface temperature and acid condensation concentration. When the wall temperature of heating surface reaches acid dew point, sulfuric acid vapor begins to condense and dew point corrosion begins to occur. Usually for boilers with high sulphur content in flue gas, the corrosion of metal wall temperature on heating surface is lighter when it is higher than dew point 25 C and lower than 105 C, and the corrosion rate is less than 0.2mm/a. When the metal wall temperature is lower than acid dew point 30-50 C, the corrosion is serious. The dew point of boiler flue gas is generally about 40 C. When the volume fraction of sulfur trioxide in flue gas exceeds 0.005%, the acid dew point of flue gas can reach 150 C. The higher the dew point temperature is, the more serious the low temperature corrosion is. Because the sub-economizer is located in the lowest temperature region of flue gas and feed water, the flue gas temperature is usually 130-180 degrees C, the water temperature is about 60-120 degrees C, and the metal wall temperature of the heating surface tube in the tube box is about 100-150 degrees C, which is very close to the acid dew point, so it is very easy to occur in this region. Low temperature corrosion, which is the main reason for the corrosion of the heating surface tubes of the sub-economizer

Although soft water is in the tube of the sub-economizer, the corrosion of 20 steel in soft water is also a problem. For carbon steel, the corrosion rate is greatly affected by temperature, and the main influence is concentrated at more than 50 C. The corrosion rate of carbon steel increases fastest in the period of 50-60 C. After 60 C, the corrosion rate increases slowly with the increase of temperature, but it is still very large compared with before 50 C. In actual production, the water inlet temperature of the sub-economizer is 60 C, which is at the stage of the fastest increase in the corrosion rate of carbon steel. Therefore, there is also the problem of corrosion on the inner wall of the furnace tube, which is one of the reasons for the corrosion of the heating surface tubes of the sub-economizer, but there is no serious low-temperature corrosion. The water leakage accident of heating surface pipes occurred in the auxiliary economizer of a steel enterprise because of low temperature dew point corrosion. After inspection, it was found that the overall corrosion on the surface of the heated surface pipe was very serious, and the average corrosion depth was more than 2 mm, which seriously affected the pressure bearing capacity of the pipe, and finally had to be replaced as a whole. The actual service life of the auxiliary economizer is only about 4 years.

2. Characteristics and corrosion resistance of ND steel pipe

ND steel pipe is a kind of steel pipe which can resist both sulfuric acid dew point corrosion and atmospheric corrosion. It is widely used in boiler economizer, air preheater, heat exchanger and evaporator with high sulfur content in flue gas. At present, ND steel pipes have been compiled into GB150.1-4-2011 Pressure Vessels, GB/T16507.1-8-2013 Water Pipe Boiler, GB/T16508.1-8-2013 Boiler Shell Boiler, NB/T47019-2011 Boiler and Heat Exchanger. Technical Conditions for Pipe Ordering Part 2: Non-alloy Steel and Alloy Steel with Room Temperature Performance, etc. have not been included in GB/T9222-2008 Standard for Strength Calculation of Compressed Components of Water Pipe Boilers. There are many successful application cases in heating surface pipes such as economizers of medium and low pressure boilers, but economizers and subsidiary economizers of CDQ boilers. The application of coal appliances is seldom documented。

ND steel has high sulfuric acid corrosion resistance because it can form a passivation film rich in copper, chromium, antimony, titanium and other elements on the surface during corrosion. The results of laboratory tests show that the corrosion rate of ND steel is much lower than that of 20 steel, which can reach 7.32 times of that of 20 steel, after 6 hours immersion in 50% H2SO4 solution at 70 C. Compared with 20 and Q235B steel grades, ND steel has obvious corrosion resistance, as shown in Table 1. The result of actual use is also good.

The results show that the service life of the equipment made of ND steel is much longer than that of 20 steel, which can be more than twice as long. The chemical composition and mechanical properties of ND steel and 20 steel are shown in Tables 2 and 3 respectively.

Table 3. Mechanical properties of ND steel and 20 steel

It can be seen from Table 2 that the low temperature dew point corrosion resistance of ND steel is better than that of 20 steel due to the addition of a small amount of copper, chromium, antimony and titanium. From the data in Table 3, it can be seen that the mechanical properties of ND steel and 20 steel are basically similar. Considering the mechanical strength, the preliminary judgement that ND steel is used instead of 20 steel can meet the requirements.

3. Strength Check of Heating Surface Pipe

The heating surface pipe of the auxiliary economizer is a serpentine pipe welded by a horizontal straight pipe and a 180 degree elbow pipe. According to the relevant provisions of GB/T9222-2008 "Strength Calculation of Pressure Components of Water Pipe Boiler", when ND steel pipe is used to manufacture heating surface pipe, the strength checking calculation of straight pipe and elbow section is as follows.

3.1Strength Checking Calculation of 3.1 Straight Pipe Section

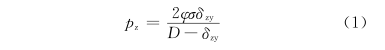

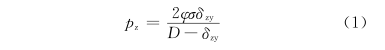

See formula (1) for strength checking calculation of straight pipe section.

In the formula: PZ is the maximum allowable calculation pressure for straight pipe check calculation, MPa; φ is the weld weakening factor; σ is the allowable stress of steel pipe, MPa; Delta elongation; delta δZY is the effective thickness of straight pipe, mm;D is the outer diameter of steel pipe, mm

According to the working conditions of the auxiliary economizer, the size of the heating surface pipe remains unchanged, and it is still 28mm *4mm. The actual working wall temperature of the pipe does not exceed 220 C, so the calculated wall temperature is 250 C. Because GB/T9222 and GB/T16508 have not given the allowable stress value of ND steel, this brings certain inconvenience to boiler design and calculation. At this temperature, the allowable stress value of ND steel pipe for pressure vessel calculation is 128MPa by inquiring GB150 standard. Because the safety factor of GB150 is different from that of GB/T9222, the allowable stress given in GB150 needs to be converted to be used as the allowable stress value of GB/T9222. After calculation_=136 MPa, the specific calculation process is omitted.

Pipe diameter D = 28mm

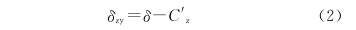

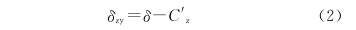

See formula for calculating effective thickness of straight pipe (2).

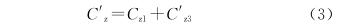

In the formula, the thickness of the steel tube is taken as the thickness of the steel tube. In this example, the thickness of the steel tube is 4 mm. In the checking calculation, the additional thickness of the straight tube is calculated according to formula (3), taking into account the corrosion thinning, process thinning and the negative deviation of the thickness of the steel tube.

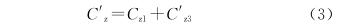

In the formula: Cz1 is the additional thickness of steel tube corrosion thinning, mm, while C'z3 is the additional thickness of steel tube thickness negative deviation, mm.

According to GB/T9222-2008 standard, corrosion thinning of steel pipe,Cz1 is 1.0mm. According to the inquiry standard GB9948-2006, the allowable deviation of wall thickness for hot-rolled steel pipes with outer diameter less than 50 mm is (+0.5 mm), so C'z3 is 0.5 mm. According to formula (2) and formula (3), the additional thickness C'z=1+0.5=1.5mm and the effective thickness of straight tube Delta zy=4-1.5=2.5mm can be obtained.

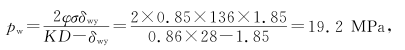

According to formula (1), the permissible pressure of ND steel pipe with size of 28mm *4mm is pz= (2 *0.85 *136 *2.5)/(28-2.5)= 22.7MPa, which is larger than the calculated pressure of 1.5MPa, so the straight pipe can meet its strength requirements.

3.2 Strength Checking Calculation of Bend Section

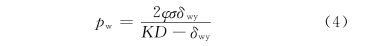

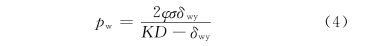

The elbow section of the heating surface pipe of the auxiliary economizer is usually formed by bending the steel pipe, so its size is the same as that of the straight pipe section, both of which are 28mm x 4mm in size. Strength checking calculation of elbow section is similar to that of straight section. See Formula (4). The difference is that the process thinning additional quantity of steel tube in bending process should be considered in strength checking calculation of elbow section.

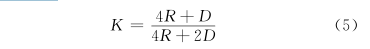

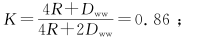

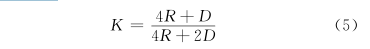

Formula: PW is the maximum allowable calculation pressure for elbow check calculation, MPa; delta WY is the effective thickness of elbow, mm; K is the shape factor of elbow, calculated according to formula (5).

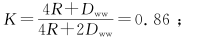

Formula: R is the radius of the elbow, 37.5 mm.

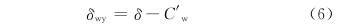

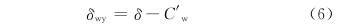

The effective thickness of the elbow is calculated by formula (6).

In formula C'w is the additional thickness of corrosion thinning, process thinning and negative deviation of steel tube thickness when checking calculation. The additional thickness of elbow section C'is calculated according to formula (7).

In the formula: Cw1 is the additional thickness of steel pipe corrosion thinning, mm; C'w2 is the additional thickness of steel pipe process thinning, mm; C'w3 is the additional thickness of steel pipe thickness negative deviation, mm.

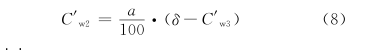

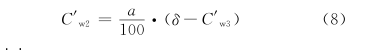

The values of Cw1 and C'w3 are the same as those of straight pipe, i.e. Cw1 = 1.0mm and C'w3 = 0.5mm. The additional thickness C'w2 of the elbow formed by steel tube, such as process thinning, is calculated according to formula (8).

among

among

Formula A is the technological coefficient of the elbow.

Formula A is the technological coefficient of the elbow.

According to formula (9), a=18.67 can be obtained. According to Formula (4)~Formula (8) It can be calculated that C'w 2=0.65 mm and C'w=0.65 mm.

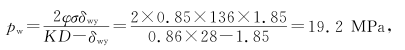

2.15 mm, delta WY = 1.85 mm;

The calculated pressure is 1.5 MPa, so it can meet the strength requirement of elbow section.

The calculated pressure is 1.5 MPa, so it can meet the strength requirement of elbow section.

According to the above calculation results, it can be seen that the strength of 28mm * 4mm ND steel pipe can meet the strength requirements of the heating surface pipe of the auxiliary economizer, and can completely replace the 20 steel pipe.

4.Implementation of ND Steel Pipe Used in Sub-economizer

For newly-built dry quenching coke, the boiler manufacturer is required to design and manufacture according to ND steel pipe material directly when ordering the equipment; for the dry quenching coke device which has been put into use, the replacement of the original auxiliary economizer is arranged by technical transformation when it reaches its service life. According to the structural characteristics of the auxiliary economizer equipment, there are usually two ways to replace the heating surface pipe: one is to replace the heating surface pipe only, retain the outer shell, header, upper and lower flue, support frame, etc; the other is to replace the upper and lower tube boxes as a whole, including tube bundles, outer shell and header, only retain the upper and lower flue and support frame, etc. Compared with the former, the cost of spare parts is relatively low, but the construction is difficult. Because of the connection between header and segment

It is difficult to ensure the quality of pipe welding and the sealing of the box through the pipe, and the construction cost is relatively high. For the latter, the cost of spare parts is relatively high, but field construction is easy. Because the connection between header and segment is welded in the factory, the sealing quality of the weld seam and the through-pipe part of the box body is better, and the construction cost on site is relatively low. The author adopts the method of replacing the upper and lower tube boxes as a whole.

When ordering spare parts, the author requests the boiler manufacturer to change the material of heating surface pipe from 20 steel pipe to ND steel pipe only. The specification and quantity of the pipe are the same as before. Because the header is placed outside the pipe box, not in contact with the flue gas, there is no low temperature corrosion problem, so the header material is still made of 20 steel to save spare parts costs. Despite the flue gas corrosion of the outer shell of the box, it has little influence on the production of CDQ due to the non-pressure, so the original design material remains unchanged. When making spare parts in factories, the relevant standards of boilers should be strictly enforced, and the welding quality of serpentine segments should be well controlled. The carbon equivalent of 09CrCuSb steel ranges from 0.34 to 0.48, which indicates that the hardening tendency of 09CrCuSb steel is small and it is not very sensitive to cold cracking. Manual TIG welding is the best welding method for sub-economizer tubes with thickness not more than 6 mm. 09CrCuSb wire with diameter of 2.0 is selected. The welding current is 80-120 A, the welding speed is 2-5 cm/min, and the argon flow rate is 8-10 L/min. Welding parameters can ensure welding quality. In addition, before leaving the factory and installing the equipment, we must do a good job of hydraulic strength test and leakage inspection, so that there will be no quality problems.

Since the company's transformation in 2013, the operation of the sub-economizer has been stable. After three years of maintenance and shutdown inspection, the internal heating surface pipe can hardly see the corrosion phenomenon. Practice has proved that ND steel pipe has been successfully applied to the heating surface tube of the auxiliary economizer of CDQ.

5. Economic Benefit Analysis of ND Steel Pipe

The material of heating surface pipe of auxiliary economizer is changed from 20 steel pipe to ND steel pipe. Its economic benefits are mainly embodied in saving spare parts and construction costs, and reducing the loss of shutdown caused by water leakage. (1) Cost of spare parts. According to the current steel price, the cost of spare parts of auxiliary economizer made of 20 steel pipes for heating surface pipes is about 700,000 yuan. If ND steel pipes are used instead, the cost of spare parts is about 1 million yuan, the difference between them is about 300,000 yuan. The actual life of the auxiliary economizer made of 20 steel pipes is calculated according to five years, and the annual average cost of spare parts is about 140,000 yuan. If ND steel pipe is used, the service life of auxiliary economizer can be extended to 10 years, and the average annual spare parts cost is about 100,000 yuan. The annual spare parts cost can be saved by about 40,000 yuan, and about 400,000 yuan can be saved by 10 years. (2) Construction cost. By calculating the 5-year life cycle of 20 steel sub-economizer and 10-year life cycle of ND steel sub-economizer, 20 steel will replace the sub-economizer tube box once in 10 years. The overhaul cost is about 200,000 yuan, the external insulation cost is about 50,000 yuan, and the total construction cost is about 250,000 yuan.

Based on the above analysis, taking 10 years as calculation period, ND steel can save 650,000 yuan compared with 20 steel, with an average annual cost saving of 65,000 yuan. If the loss of shutdown caused by water leakage is considered, the economic benefit will be more obvious.

6. summary

Through theoretical calculation and practice, it is proved that ND steel pipe is not only technically feasible, but also can obviously enhance its corrosion resistance, and has good economic benefits. It is suggested that ND steel pipe be widely used in the manufacture of heating surface tubes of sub-economizer.

The problem of boiler leakage and tube burst is one of the greatest threats to the normal production of CDQ at present. It has the characteristics of sudden accident, relatively long shutdown time, difficulty in rush repair and great economic loss. There are many reasons for boiler leakage and tube burst, one of which is the corrosion of heating surface tubes. According to the investigation of relevant institutions, almost all economizers and sub-economizers of CDQ boilers in China use carbon steel tubes as heating surface tubes, which have poor corrosion resistance. Water leakage due to corrosion generally occurs within 3-5 years, and the service life of equipment is generally only 5-8 years. As the feed water preheater of CDQ boiler, the secondary economizer is affected by low temperature flue gas dew point corrosion, which has higher probability of water leakage and shorter service life. Once the furnace tube needs to be replaced, the cost of spare parts, construction and insulation is higher. If the loss caused by the shutdown of coke dry quenching is considered, the economic loss will be greater. Therefore, it is of great significance to study the low temperature dew point corrosion resistance of the heating surface tubes of the auxiliary economizer.

In order to slow down the corrosion rate of heating surface pipes in low temperature zone, there are usually two ways: one is to increase the flue gas and feed water temperature in the sub-economizer area to avoid condensation of sulfuric acid vapor and water vapor; the other is to select steel pipes with low temperature dew point corrosion resistance to make heating surface pipes to improve their corrosion resistance. In fact, it is very difficult to increase the flue gas and water temperature in the sub-economizer area of CDQ. Therefore, it is a relatively safe method to use ND steel pipe to manufacture heating surface tubes at present. In this paper, ND steel pipe is used to replace the original 20 steel pipe to manufacture the heating surface tube of the sub-economizer. It is hoped that the heating surface tube of the sub-economizer can be improved by improving the material.Resistance to low temperature dew point corrosion.

1. Cause Analysis of Corrosion of Sub-economizer Pipe

The auxiliary economizer is a preheater before deaeration of feed water of CDQ boiler. It is installed between the outlet of circulating fan and the inlet of chamber of CDQ trough, so it is also called feed water preheater. Usually, light tube contact is used for heat transfer, which consists of upper tube box, lower tube box, bottom flue, top flue and external frame. The upper and lower tube boxes are composed of 68 groups of segments, outer shell of the box and upper and lower headers respectively. Each group of segments is a serpentine pipe welded by 16 layers of horizontal straight pipe and 180 degree elbow pipe. Water and flue gas enter from the lower tube box of the sub-economizer and flow out from the upper tube box. The heating surface of the tube is generally made of 20 steel pipes with a specification of 28 mm x 4 mm (GB3087). The maximum operating pressure of the pipe is 1.47 MPa, the water supply is about 82.1 t/h, the inlet temperature is about 60 C, the outlet temperature is about 120 C, the inlet temperature is usually 160-180 C, and the outlet temperature is usually 120-130 C. The maximum flue gas flow rate is about 214 000 m3/h, the total heat transfer area is 940 m2, and the total weight of the tube bundle is about 28 t.

Among the chemical substances that produce waste gas from coke oven coking, the mass concentration of hydrogen sulfide is generally not more than 6g/m_, the mass concentration of HNC is not more than 1.5g/m_and the volume fraction of carbon dioxide is 2.3%. Therefore, the smoke of CDQ will inevitably carry dust, water vapor, sulfide, cyanide and so on. Harmful substances. Water vapor is easy to dew in low temperature flue gas, and reacts with sulfide to form dilute sulfuric acid, which results in corrosion. This is low temperature corrosion. The mechanism of low temperature corrosion of flue gas is that water vapor and sulfuric acid vapor in low temperature flue gas condense on the low temperature heating surface of boiler, and pitting corrosion occurs in chemical reaction with furnace tube metals, and pitting corrosion occurs preferentially on ferrite near grain boundary. When the pit grows up, it develops preferentially along the rolling direction, forming corrosion grooves, resulting in thinning of wall thickness and mechanical strength of pipe wall.

Reduce water leakage through perforation until failure. The formation of low temperature corrosion depends on three factors: acid deposition, heating surface temperature and acid condensation concentration. When the wall temperature of heating surface reaches acid dew point, sulfuric acid vapor begins to condense and dew point corrosion begins to occur. Usually for boilers with high sulphur content in flue gas, the corrosion of metal wall temperature on heating surface is lighter when it is higher than dew point 25 C and lower than 105 C, and the corrosion rate is less than 0.2mm/a. When the metal wall temperature is lower than acid dew point 30-50 C, the corrosion is serious. The dew point of boiler flue gas is generally about 40 C. When the volume fraction of sulfur trioxide in flue gas exceeds 0.005%, the acid dew point of flue gas can reach 150 C. The higher the dew point temperature is, the more serious the low temperature corrosion is. Because the sub-economizer is located in the lowest temperature region of flue gas and feed water, the flue gas temperature is usually 130-180 degrees C, the water temperature is about 60-120 degrees C, and the metal wall temperature of the heating surface tube in the tube box is about 100-150 degrees C, which is very close to the acid dew point, so it is very easy to occur in this region. Low temperature corrosion, which is the main reason for the corrosion of the heating surface tubes of the sub-economizer

Although soft water is in the tube of the sub-economizer, the corrosion of 20 steel in soft water is also a problem. For carbon steel, the corrosion rate is greatly affected by temperature, and the main influence is concentrated at more than 50 C. The corrosion rate of carbon steel increases fastest in the period of 50-60 C. After 60 C, the corrosion rate increases slowly with the increase of temperature, but it is still very large compared with before 50 C. In actual production, the water inlet temperature of the sub-economizer is 60 C, which is at the stage of the fastest increase in the corrosion rate of carbon steel. Therefore, there is also the problem of corrosion on the inner wall of the furnace tube, which is one of the reasons for the corrosion of the heating surface tubes of the sub-economizer, but there is no serious low-temperature corrosion. The water leakage accident of heating surface pipes occurred in the auxiliary economizer of a steel enterprise because of low temperature dew point corrosion. After inspection, it was found that the overall corrosion on the surface of the heated surface pipe was very serious, and the average corrosion depth was more than 2 mm, which seriously affected the pressure bearing capacity of the pipe, and finally had to be replaced as a whole. The actual service life of the auxiliary economizer is only about 4 years.

2. Characteristics and corrosion resistance of ND steel pipe

ND steel pipe is a kind of steel pipe which can resist both sulfuric acid dew point corrosion and atmospheric corrosion. It is widely used in boiler economizer, air preheater, heat exchanger and evaporator with high sulfur content in flue gas. At present, ND steel pipes have been compiled into GB150.1-4-2011 Pressure Vessels, GB/T16507.1-8-2013 Water Pipe Boiler, GB/T16508.1-8-2013 Boiler Shell Boiler, NB/T47019-2011 Boiler and Heat Exchanger. Technical Conditions for Pipe Ordering Part 2: Non-alloy Steel and Alloy Steel with Room Temperature Performance, etc. have not been included in GB/T9222-2008 Standard for Strength Calculation of Compressed Components of Water Pipe Boilers. There are many successful application cases in heating surface pipes such as economizers of medium and low pressure boilers, but economizers and subsidiary economizers of CDQ boilers. The application of coal appliances is seldom documented。

ND steel has high sulfuric acid corrosion resistance because it can form a passivation film rich in copper, chromium, antimony, titanium and other elements on the surface during corrosion. The results of laboratory tests show that the corrosion rate of ND steel is much lower than that of 20 steel, which can reach 7.32 times of that of 20 steel, after 6 hours immersion in 50% H2SO4 solution at 70 C. Compared with 20 and Q235B steel grades, ND steel has obvious corrosion resistance, as shown in Table 1. The result of actual use is also good.

The results show that the service life of the equipment made of ND steel is much longer than that of 20 steel, which can be more than twice as long. The chemical composition and mechanical properties of ND steel and 20 steel are shown in Tables 2 and 3 respectively.

Table 1 Corrosion resistance of ND steel and other steels

| Steel grade | Corrosion rate/(mg.cm-2.h-1) | Times |

| ND | 7.3 | 1.00 |

| CRIR | 13.4 | 1.84 |

| 1Cr18Ni9 | 21.7 | 2.97 |

| 20 | 53.4 | 7.32 |

| Corten | 63.0 | 8.63 |

| A3 ( Q235B ) | 103.5 | 14.11 |

Table 2. Chemical Constituents of ND Steel and 20 Steel ,%

| Grade | C | Si | Mn | S | P | Cr | Cu | Ti | Sb |

| ND | ≤0.12 | 0.20-0.40 | 0.35~0.65 | ≤0.02 | ≤0.03 | 0.70~1.10 | 0.25~0.45 | ≤0.10 | 0.04~0.10 |

| 20# | 0.17-0.23 | 0.17-0.37 | 0.35~0.65 | ≤0.02 | ≤0.03 | ≤0.25 | ≤0.20 | - | - |

Table 3. Mechanical properties of ND steel and 20 steel

| Grade | OD /mm | Tensile test | ||

| Tensile strength | Yield strength | Elongation | ||

| ND Steel | ≤8 | 390~550 | ≥245 | ≥25 |

| 20 Steel | ≤16 | 410~550 | ≥245 | ≥24 |

It can be seen from Table 2 that the low temperature dew point corrosion resistance of ND steel is better than that of 20 steel due to the addition of a small amount of copper, chromium, antimony and titanium. From the data in Table 3, it can be seen that the mechanical properties of ND steel and 20 steel are basically similar. Considering the mechanical strength, the preliminary judgement that ND steel is used instead of 20 steel can meet the requirements.

3. Strength Check of Heating Surface Pipe

The heating surface pipe of the auxiliary economizer is a serpentine pipe welded by a horizontal straight pipe and a 180 degree elbow pipe. According to the relevant provisions of GB/T9222-2008 "Strength Calculation of Pressure Components of Water Pipe Boiler", when ND steel pipe is used to manufacture heating surface pipe, the strength checking calculation of straight pipe and elbow section is as follows.

3.1Strength Checking Calculation of 3.1 Straight Pipe Section

See formula (1) for strength checking calculation of straight pipe section.

In the formula: PZ is the maximum allowable calculation pressure for straight pipe check calculation, MPa; φ is the weld weakening factor; σ is the allowable stress of steel pipe, MPa; Delta elongation; delta δZY is the effective thickness of straight pipe, mm;D is the outer diameter of steel pipe, mm

According to the working conditions of the auxiliary economizer, the size of the heating surface pipe remains unchanged, and it is still 28mm *4mm. The actual working wall temperature of the pipe does not exceed 220 C, so the calculated wall temperature is 250 C. Because GB/T9222 and GB/T16508 have not given the allowable stress value of ND steel, this brings certain inconvenience to boiler design and calculation. At this temperature, the allowable stress value of ND steel pipe for pressure vessel calculation is 128MPa by inquiring GB150 standard. Because the safety factor of GB150 is different from that of GB/T9222, the allowable stress given in GB150 needs to be converted to be used as the allowable stress value of GB/T9222. After calculation_=136 MPa, the specific calculation process is omitted.

Pipe diameter D = 28mm

See formula for calculating effective thickness of straight pipe (2).

In the formula, the thickness of the steel tube is taken as the thickness of the steel tube. In this example, the thickness of the steel tube is 4 mm. In the checking calculation, the additional thickness of the straight tube is calculated according to formula (3), taking into account the corrosion thinning, process thinning and the negative deviation of the thickness of the steel tube.

In the formula: Cz1 is the additional thickness of steel tube corrosion thinning, mm, while C'z3 is the additional thickness of steel tube thickness negative deviation, mm.

According to GB/T9222-2008 standard, corrosion thinning of steel pipe,Cz1 is 1.0mm. According to the inquiry standard GB9948-2006, the allowable deviation of wall thickness for hot-rolled steel pipes with outer diameter less than 50 mm is (+0.5 mm), so C'z3 is 0.5 mm. According to formula (2) and formula (3), the additional thickness C'z=1+0.5=1.5mm and the effective thickness of straight tube Delta zy=4-1.5=2.5mm can be obtained.

According to formula (1), the permissible pressure of ND steel pipe with size of 28mm *4mm is pz= (2 *0.85 *136 *2.5)/(28-2.5)= 22.7MPa, which is larger than the calculated pressure of 1.5MPa, so the straight pipe can meet its strength requirements.

3.2 Strength Checking Calculation of Bend Section

The elbow section of the heating surface pipe of the auxiliary economizer is usually formed by bending the steel pipe, so its size is the same as that of the straight pipe section, both of which are 28mm x 4mm in size. Strength checking calculation of elbow section is similar to that of straight section. See Formula (4). The difference is that the process thinning additional quantity of steel tube in bending process should be considered in strength checking calculation of elbow section.

Formula: PW is the maximum allowable calculation pressure for elbow check calculation, MPa; delta WY is the effective thickness of elbow, mm; K is the shape factor of elbow, calculated according to formula (5).

Formula: R is the radius of the elbow, 37.5 mm.

The effective thickness of the elbow is calculated by formula (6).

In formula C'w is the additional thickness of corrosion thinning, process thinning and negative deviation of steel tube thickness when checking calculation. The additional thickness of elbow section C'is calculated according to formula (7).

In the formula: Cw1 is the additional thickness of steel pipe corrosion thinning, mm; C'w2 is the additional thickness of steel pipe process thinning, mm; C'w3 is the additional thickness of steel pipe thickness negative deviation, mm.

The values of Cw1 and C'w3 are the same as those of straight pipe, i.e. Cw1 = 1.0mm and C'w3 = 0.5mm. The additional thickness C'w2 of the elbow formed by steel tube, such as process thinning, is calculated according to formula (8).

According to formula (9), a=18.67 can be obtained. According to Formula (4)~Formula (8) It can be calculated that C'w 2=0.65 mm and C'w=0.65 mm.

2.15 mm, delta WY = 1.85 mm;

The calculated pressure is 1.5 MPa, so it can meet the strength requirement of elbow section.

The calculated pressure is 1.5 MPa, so it can meet the strength requirement of elbow section.According to the above calculation results, it can be seen that the strength of 28mm * 4mm ND steel pipe can meet the strength requirements of the heating surface pipe of the auxiliary economizer, and can completely replace the 20 steel pipe.

4.Implementation of ND Steel Pipe Used in Sub-economizer

For newly-built dry quenching coke, the boiler manufacturer is required to design and manufacture according to ND steel pipe material directly when ordering the equipment; for the dry quenching coke device which has been put into use, the replacement of the original auxiliary economizer is arranged by technical transformation when it reaches its service life. According to the structural characteristics of the auxiliary economizer equipment, there are usually two ways to replace the heating surface pipe: one is to replace the heating surface pipe only, retain the outer shell, header, upper and lower flue, support frame, etc; the other is to replace the upper and lower tube boxes as a whole, including tube bundles, outer shell and header, only retain the upper and lower flue and support frame, etc. Compared with the former, the cost of spare parts is relatively low, but the construction is difficult. Because of the connection between header and segment

It is difficult to ensure the quality of pipe welding and the sealing of the box through the pipe, and the construction cost is relatively high. For the latter, the cost of spare parts is relatively high, but field construction is easy. Because the connection between header and segment is welded in the factory, the sealing quality of the weld seam and the through-pipe part of the box body is better, and the construction cost on site is relatively low. The author adopts the method of replacing the upper and lower tube boxes as a whole.

When ordering spare parts, the author requests the boiler manufacturer to change the material of heating surface pipe from 20 steel pipe to ND steel pipe only. The specification and quantity of the pipe are the same as before. Because the header is placed outside the pipe box, not in contact with the flue gas, there is no low temperature corrosion problem, so the header material is still made of 20 steel to save spare parts costs. Despite the flue gas corrosion of the outer shell of the box, it has little influence on the production of CDQ due to the non-pressure, so the original design material remains unchanged. When making spare parts in factories, the relevant standards of boilers should be strictly enforced, and the welding quality of serpentine segments should be well controlled. The carbon equivalent of 09CrCuSb steel ranges from 0.34 to 0.48, which indicates that the hardening tendency of 09CrCuSb steel is small and it is not very sensitive to cold cracking. Manual TIG welding is the best welding method for sub-economizer tubes with thickness not more than 6 mm. 09CrCuSb wire with diameter of 2.0 is selected. The welding current is 80-120 A, the welding speed is 2-5 cm/min, and the argon flow rate is 8-10 L/min. Welding parameters can ensure welding quality. In addition, before leaving the factory and installing the equipment, we must do a good job of hydraulic strength test and leakage inspection, so that there will be no quality problems.

Since the company's transformation in 2013, the operation of the sub-economizer has been stable. After three years of maintenance and shutdown inspection, the internal heating surface pipe can hardly see the corrosion phenomenon. Practice has proved that ND steel pipe has been successfully applied to the heating surface tube of the auxiliary economizer of CDQ.

5. Economic Benefit Analysis of ND Steel Pipe

The material of heating surface pipe of auxiliary economizer is changed from 20 steel pipe to ND steel pipe. Its economic benefits are mainly embodied in saving spare parts and construction costs, and reducing the loss of shutdown caused by water leakage. (1) Cost of spare parts. According to the current steel price, the cost of spare parts of auxiliary economizer made of 20 steel pipes for heating surface pipes is about 700,000 yuan. If ND steel pipes are used instead, the cost of spare parts is about 1 million yuan, the difference between them is about 300,000 yuan. The actual life of the auxiliary economizer made of 20 steel pipes is calculated according to five years, and the annual average cost of spare parts is about 140,000 yuan. If ND steel pipe is used, the service life of auxiliary economizer can be extended to 10 years, and the average annual spare parts cost is about 100,000 yuan. The annual spare parts cost can be saved by about 40,000 yuan, and about 400,000 yuan can be saved by 10 years. (2) Construction cost. By calculating the 5-year life cycle of 20 steel sub-economizer and 10-year life cycle of ND steel sub-economizer, 20 steel will replace the sub-economizer tube box once in 10 years. The overhaul cost is about 200,000 yuan, the external insulation cost is about 50,000 yuan, and the total construction cost is about 250,000 yuan.

Based on the above analysis, taking 10 years as calculation period, ND steel can save 650,000 yuan compared with 20 steel, with an average annual cost saving of 65,000 yuan. If the loss of shutdown caused by water leakage is considered, the economic benefit will be more obvious.

6. summary

Through theoretical calculation and practice, it is proved that ND steel pipe is not only technically feasible, but also can obviously enhance its corrosion resistance, and has good economic benefits. It is suggested that ND steel pipe be widely used in the manufacture of heating surface tubes of sub-economizer.